Here is your chance to make an impression with the S22K PVC card printer, a smart card printer making the process so much easier and enjoyable. With a PVC card printing machine, you can make edge-to-edge printing for a more professional card appearance. PVC card printer promises high efficacy, produces large quantities at low costs and a variety of card encoding modules.

What’s more, this PVC card printer lets you print in a single press and produces high-quality graphics making it perfect to use at large events where authentication counts. Below is 7 Steps to Get started with the S22k PVC Card Printer.

When you open the top cover of the box, you will find the PE foam, accessories box, and the S22K card printer. Check the following accessories that much be present in the box:

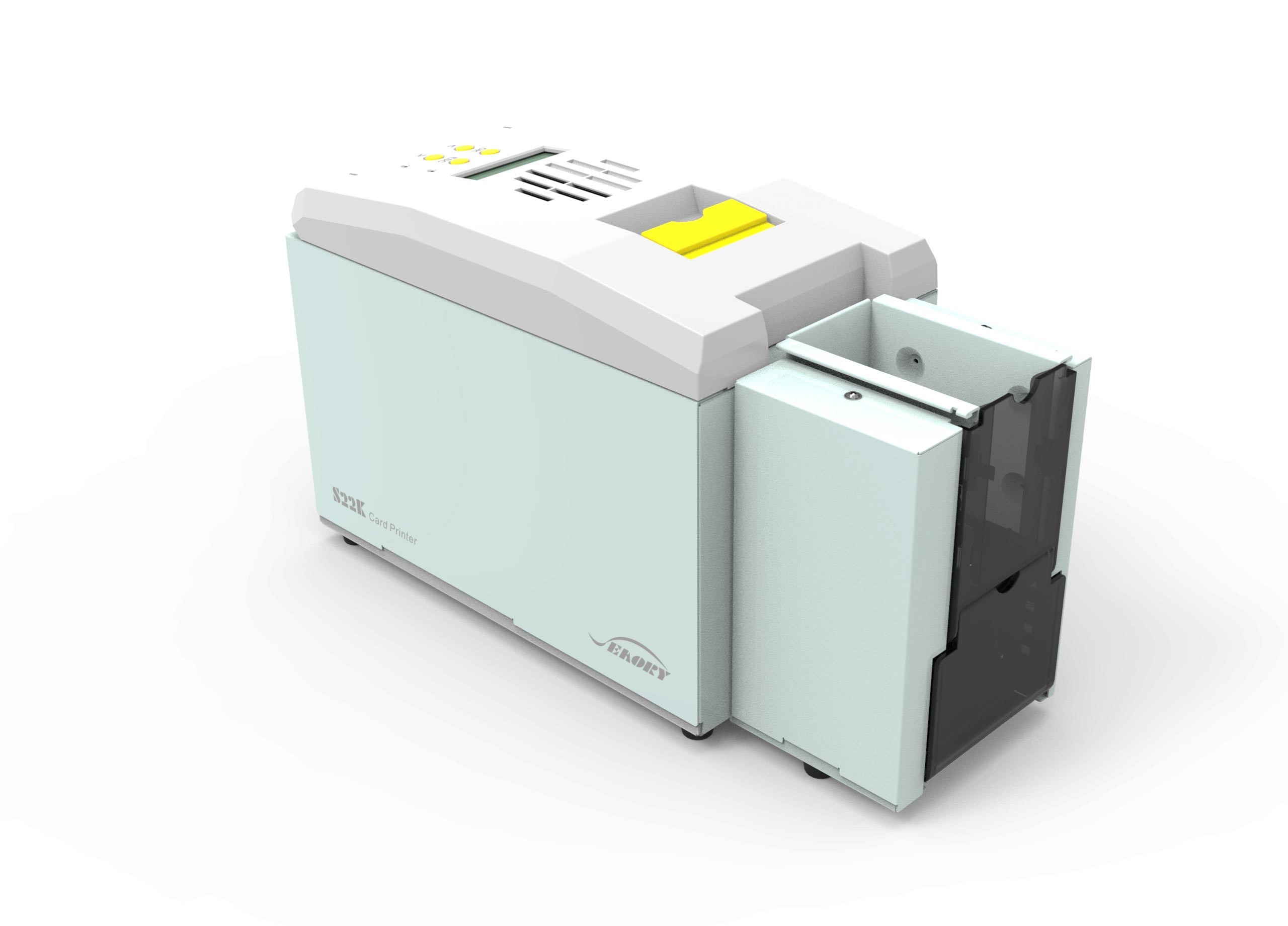

If the accessories are complete, the first step is to install the cleaning roller. When installing the cleaning roller, gently lift the upper cover switch on the PVC card printer (the switch is yellow), and then take out the ribbon box inside. At this time, the 3M transparent layer on the surface of the cleaning roller should be removed. Finally, hold one side of the cleaning roller with thumb and index finger, push it into the installation position and press it down slightly.

After installing the cleaning roller, you can start to install the ribbon. There are color marks on the ribbon box of the S22K PVC card printer, which can be loaded into the ink cartridge according to the color direction. The red roller supplies with unused ribbons and the white rollers supply with used ribbons. The ribbon cartridge is installed on one side of the ribbon box, which is the red drum closed to the exit of the rear card.

Before running the PVC card printing machine, it needs to put the PVC card into the input hopper. The chip is required to face up if printing contact the chip cards; otherwise, the data cannot be read or written into the chip card. Then add the weight module which is to increase the friction between the card and the roller so that the paper feeding of the card is smoothy.

Because the thickness of different cards is different, it is necessary to adjust the thickness of the card feeding entrance before using the PVC card printing machine. To adjust the thickness of the card feeding entrance, just move the yellow control lever to adjust the thickness of the paper feeding card. S22k PVC card printer supports 0.3mm to 0.1mm thick cards.

The driver is installed to connect the S22K PVC card printer with the computer so as to realize the design of the card on the computer. It is important to note that do not turn on the power of the PVC card printer before the driver is installed. To install the driver, you need to use CD-ROM or download the driver installation package from the official website of Seaory. Double click the driver installation package, and then follow the prompts to complete. Turn on the power switch after the above steps are completed and the driver will be installed automatically. Finally, click "control panel - hardware and sound - devices and printers" and you will find that the Seaory S22K PVC card printer is fully installed.

Relevant software can be used to print and test the PVC card printer after driver installation. You can also use Seaory's “ICARDE” software for print testing.

Getting started with the S22K PVC card printer is really easy if you follow all the steps. Print custom designed cards with PVC card printing machine without any hassle! Want to know what else you can do with your PVC card printers? Head towards our website and explore how you can make your business grow with our services and products.