Dye Sublimation printing technology is not as familiar as ink-jet and laser printing technology in the field of office, but it has unique advantages in photo output, fabric and cup body transfer printing.Especially in the photo level output requirements of the print effect.High image resolution, natural color transition, easy to preserve and other advantages have become the preferred printing method for many color photo level output printing industry, and the main reason is because of the unique principle of dye Sublimation printing technology.

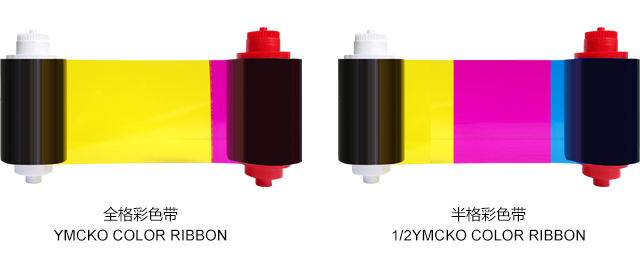

Dye Sublimation printing technology refers to the process of Sublimation from gas to solid and solid to gas without intermediate state and mutual transformation to realize the printout of photo-grade images. In other words, the solid pigments used by the printer are directly sublimated into gas phase after heating by the heat recording head, and then transferred to the printing medium to generate images.Thermal Sublimation printing USES thermal sensitivity technology to print YMCKO(yellow/magenta/cyan/black/protective film) trichromatic dye, pure black dye and a protective film, which are vaporized by heat treatment and then imprinted on the printing medium.The source of color dyes is the ribbon, which is generally composed of yellow, magenta, green and black ribbons plus a protective film. The ribbon is arranged on a drum, which is equipped with tens of thousands of semiconductor heating elements, and these heating elements constitute the print head.When the ribbon passes through the hot print head at a certain temperature, it sublimates directly into a gaseous state and is then sprayed onto the printing medium to form the color.

When printing, the printing medium and the ribbon are simultaneously heated under the printing head through a roller. The heating lattice of monocrystals with diameter less than 40μm is used on the printing head. The heating lattice of the printing head is electrified and the dry solid ink coated on the ribbon is melted.During the heating process, a wonderful transformation takes place. At about 320 degrees Fahrenheit, the heat separates the polymer molecules. When the printing head passes, the temperature drops, the ink changes from gas to solid, and the ink is embedded in the polymer.Polymer molecules stick together (which is why thermal Sublimation printing doesn't rub off), and when one color is printed, it automatically moves to the beginning for the next.The resolution depends on the heating element, and the amount of color added depends on the temperature of the heating element, sublimating the ribbon on a piece of printing medium to produce a mixture of millions of colors.So you get excellent printed picture.

The unique working principle of dye Sublimation printing technology makes its high quality output become the biggest bright spot.In terms of technology, dye Sublimation technology refers to the use of color ribbon in the printer. By heating the color dye to the paper medium, the color image is formed.In terms of performance, dye Sublimation is based on the application of technology. The resolution of 300× 300DPI is comparable to the printing precision of 4800× 4800Dpi of ink-jet printer.In the image preservation, the theoretical preservation period of the image printed out by the heat rising printer is really permanent.

Seaory card printers are 300× 300DPI by default, and can be upgraded to 300× 600DPI and 300× 1200DPI. In terms of printing accuracy, Seaory card printers can be compared with ultra-high precision inkjet printers.