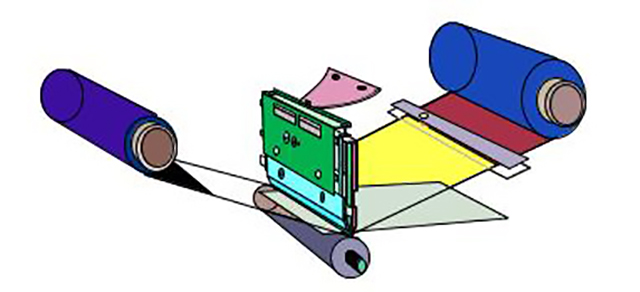

PVC Card printer technology works by running a heater print head over a ribbon, which transfers the colors to your card to make your design. With different print technologies and ribbons, you can make almost any design! Card printers work by utilizing the ink panels from a color ribbon to apply the image onto or into a PVC card.

How Card Printers Work?

Most card printers use one of two types of card printing technology – dye Sublimation or reverse transfer printing. Both technologies require a print head, a ribbon, and a blank card.

With dye Sublimation printing (also called direct to card printing), the print head applies the ribbon directly to the card. This printing method is known for its fast print speeds, making it ideal for organizations that need to quickly and efficiently print cards.

With reverse transfer printing, your design is first applied to a clear transfer film, then that film is applied to the card. This process allows for true over the edge printing because the transfer film is slightly larger than a CR80 card and will wrap completely around the face of the card. Because the print head doesn’t come into contact with the card, just the film, reverse transfer printers are recommended for printing on cards with uneven surfaces, like technology cards.

Dye-sub Card printer Advantages-

Dye-sub ID card printers are typically less expensive than reverse transfer. That is true for both the ID card printer price and the supplies pricing. We will explain why in the ID card HD printing advantages.

Dye-sub printers are faster. The ribbon is heated right into the card eliminating the mechanics of applying it to a clear film first. This means a faster printing speed.

Dye-Sub printers are typically a bit smaller too. That’s good for front desk receptionist areas or other places where space is limited or presentation is important.

Reverse Transfer card printer Advantages-

These printers have a higher quality print than a dye-sub printer. That’s the big one. Because its not injecting the image into the card, it has a better resolution.

These printers can produced a closer-to-the-edge print. The film can wrap around the edges of the card much closer. Dye-sub printers cant get as close since the print head has to touch the card and as it gets closer, pixels are missed, like following off the edge of a cliff.

Reverse transfer card printers also offer a more consistent printing experience. Less errors like ribbon wrinkle, ribbon tearing, and color matching occur.

Seaory have Different Types of Printer Ribbons

Black monochrome ribbon:100m×60mm / 200m×60mm

Gold/Silver/White/Blue monochrome ribbon:100m×60mm

Black KO ribbon:500prints per roll

Half-panel 1/2ymcKO ribbon:450prints per roll

Full-panel YMCKOK ribbon:YMCKOK,240prints per roll

Full-panel YMCKO ribbon:YMCKO,300prints per roll